Can You Freeze Dry Honey

Lead (summary)

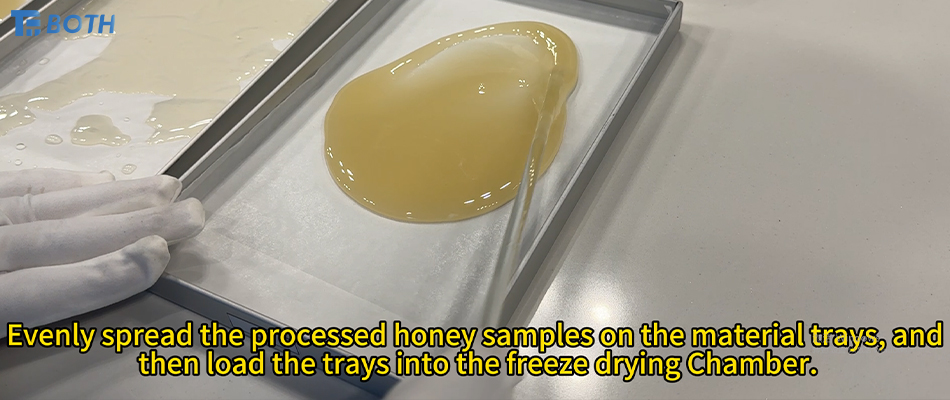

As demand grows for natural, minimally processed ingredients that keep their functionality, BOTH completed a freeze-dried honey experiment on our vacuum freeze-drying platform. By controlling solids/water baseline, shelf & product temperatures, and chamber vacuum, we produced crisp or powder formats with high rehydration, clean flavor, and strong stability—with traceable data throughout.

Stage 1 — Pre-treatment & Solids/Water Baseline (Experience)

Filtration & clarification: Remove particulates/debris while keeping honey’s natural profile intact.

Optional carrier or dilution: For very viscous batches, a small percentage of carrier (e.g., maltodextrin) or controlled dilution can improve mass transfer and porosity.

Baseline logging: Record solids and moisture with a calibrated analyzer (typical commercial honey moisture often falls around the high-teens percentage). These values feed the program curve design—shelf ramp and vacuum targets—to ensure repeatability and traceability across runs.

Recommended equipment: LFD laboratory vacuum freeze dryers for DoE/method development, viscosity handling trials, and comprehensive data logging.

Stage 2 — Program & Real-time Monitoring (Expertise)

We run a three-stage, data-logged program: Freezing → Primary Drying (sublimation) → Secondary Drying (desorption).

Freezing: Down to ≈ −35 to −40 °C to immobilize the matrix and stabilize structure.

Primary drying: ~10⁻³ mbar vacuum with controlled shelf-temperature ramp to remove free water/volatiles while keeping product temperature below the critical temperature (Tc) to prevent collapse or stickiness.

Secondary drying: Stepwise heating to remove bound water, targeting ≤ 2%–4% final moisture depending on the intended format (crisp shards, granules, or powder) and packaging.

Scale-up & production:

• PFD pilot freeze dryers — scale-up with viscous matrices and carrier optimization

• BTFD/BSFD production freeze dryers — CIP/SIP, automation, high throughput for food & nutrition formats

• BBFT aseptic stoppering freeze dryers — for biopharma-style aseptic environments or specialty SKUs

• RFD/HFD/SFD/DFD home freeze dryers — for education, demos, and content creation

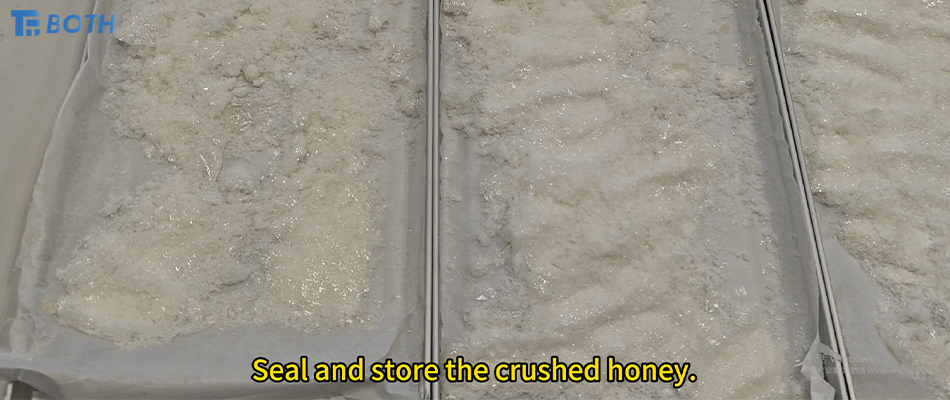

Stage 3 — Discharge & Quality Verification (Authoritativeness)

In-chamber warm-up: Slow ramp to avoid condensation and moisture uptake.

Quality endpoints:

Final moisture: typically 2%–4% (format-dependent)

Rehydration: quick dissolution or rapid rehydration with clean mouthfeel

Flavor & aroma: characteristic honey notes, low thermal impact

Texture choices: crisp shards, granules, or flowable powders for blending/coating

Micro limits: tested to internal standards with retains and stability logs

Packaging & storage: Nitrogen flushing and/or desiccant with barrier packs; store at ambient in a dry, light-protected environment to sustain crispness and prevent caking.

Benefits of freeze-dried honey (Trustworthiness)

Low-temperature preservation: Sublimation minimizes thermal degradation and helps preserve volatile aroma compounds.

Shelf-stable formats: Low residual moisture supports ambient stability, convenient dosing, and clean-label formulations.

Rehydration/dissolution: Porous structure enables fast reconstitution in beverages or rapid dispersion in dry blends.

Handling & logistics: Transforming viscous honey into a crisp or powder format improves handling, dosing accuracy, and transportation.

Market outlook: equipment stack + energy resilience

Freeze-dried ingredients are scaling across food, nutrition, and specialty applications. BOTH differentiates with a full equipment stack—LFD (lab) → PFD (pilot) → BTFD/BSFD (production) / BBFT (aseptic), plus RFD/HFD/SFD/DFD (home)—and an Energy Resilience Solution:

Freeze-Dryer Energy Storage Solution: By integrating solar PV + battery storage + EMS (energy management system), BOTH enables multi-energy coordinated power for uninterrupted operation under grid volatility while optimizing kWh/kg water removal and total cost of ownership.

Thank you for reading our latest update. If you need more information or have any questions, please don’t hesitate to contact us. Our team is here to provide support and assistance.

Post time: Nov-18-2025