-

CFE-C2 Series Industrial Direct Shaft Continuous Basket Fine Chemicals/Solvents Extraction Centrifuge

High-Efficiency Direct-Drive Structure — Zero Belt Loss, Engineered for Continuous Operation

The CFE-C2 Series utilizes a direct-drive motor configuration, significantly reducing energy consumption and failure rates compared to traditional belt-driven systems. This makes it particularly suitable for high-frequency applications requiring extended continuous operation.

Its compact design eliminates belt slippage, delivering superior power response and precise speed control. In explosion-proof environments, the absence of belt friction also minimizes static charge accumulation, enhancing operational safety.Typical Applications: #Fine chemical extraction, #flammable solvent extraction, #continuous-process extraction scenarios.

-

BOTH DFD-2 3Kg Small Desktop Lyophilizer Vacuum Automatic Food Freeze Machine Home Benchtop Freeze Dryer

New compact freeze dryer with integrated vacuum pump. Size: 585×670×575mm, capacity: 2–3kg/batch. Low energy use at only 0.9KW. Ideal for labs, R&D, and small-batch production. Available in black or white. Space-saving, efficient, and ready to use.

-

Hot Sale DMD Series Lab Scale 2L~20L Glass Short Path Distillation

Short Path Distillation is a distillation technique that involves the distillate travelling a short distance. It is method of separating mixtures based on differences in their volatilities in a boiling liquid mixture under reduced pressure. As the sample mixture to be purified is heated, its vapors rise a short distance into a vertical condenser where they are cooled by water. This technique is used for compounds which are unstable at high temperatures because it allows a lower boiling temperature to be used.

-

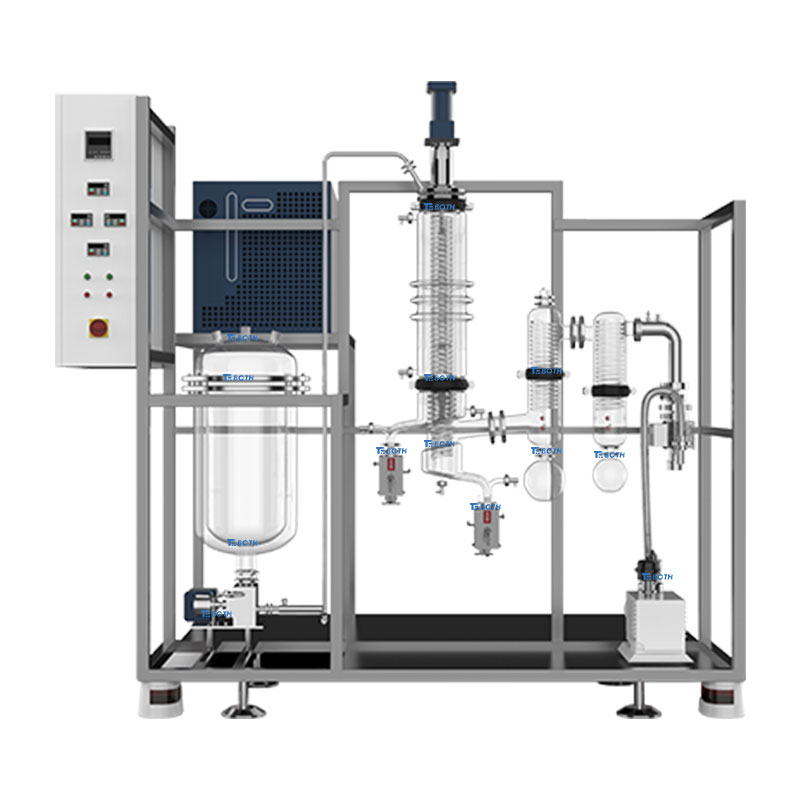

Glass Wiped Film Molecular Distillation Equipment

Molecular distillation is a special liquid-liquid separation technology, which is different from traditional distillation which relies on the principle of boiling point difference separation. This is a process of distillation and purification of heat-sensitive material or high boiling points material using the difference in the free path of molecular motion under high vacuum. Mainly used in chemical, pharmaceutical, petrochemical, spices, plastics and oil and other industrial fields.

The material is transferred from the feeding vessel to the main distillation jacketed evaporator. Through the rotation of the rotor and continuous heating, the material liquid is scrape into an extremely thin, turbulent liquid film, and pushed downward in a spiral shape. In the process of descent, the lighter material (with low boiling point) in the material liquid begins to vaporize, move to the internal condenser, and become liquid flowing down to the light phase receiving flask. Heavier materials (such as chlorophyll, salts, sugars, waxy, etc.) do not evaporate, instead, it flows along the inner wall of the main evaporator into the heavy phase receiving flask.

-

High Quality Stainless Steel Short Path Molecular Distillation Unit

Short Path Molecular Distillation is a special liquid-liquid separation technology, which is different from the traditional distillation by boiling point difference principle, but by different substances molecular movement of the average free path difference to achieve separation. So that, in the whole distillation process, material keep it’s nature and only separate different weight molecule.

When material is fed into the Wiped Film Short Path Molecular Distillation System, through the rotation of the rotor, the wipes will form a very thin film on the wall of the distiller. The smaller molecules will escape and be caught by the inner condenser firstly, and collect as Lighter Phase (Products) .While the bigger molecules flow down the wall of the distiller, and collect as Heavier Phase, which also be known as Residue.

-

2 Stages Short Path Wiped Film Distillation Machine

The 2 Stages Short Path Wiped Film Molecular Distillation has better functions than single molecular distillation like more stable vacuum and higher purity finished product. This system is capability of continuous and unattended operation. The units are available in various sizes (the effective evaporation area from 0.3m2 to industrial version), with processing speed starting from 3L/hour. Currently, we offers standard version and upgraded version stainless steel molecular distillation units (UL certificated) for a wide range of herbal oil distillation.

-

3 Stages Short Path Wiped Film Molecular Distillation Machine

The 3 Stages Short Path Wiped Film Molecular Distillation Machine is a continuous feeding & discharge distillation machine. It perform a stable vacuum condition, a perfect golden yellow Herbal oil, 30% more yield coefficient.

The machine assembles with Dehydration & Degassing Reactor, which will do the perfect pretreatment before distillation process.

The full jacketed pipelines designed in the machine are heated by an individual closed industrial heater. Magnetic drive transfer pumps between stages and the discharge gear pumps are all heat tracing ones. That will avoid any coking or block in long time running.

Vacuum pump units are made of industrial roots pump, rotary vane oil pump unit and diffusion pumps. The whole system is running in high vacuum 0.001mbr/ 0.1Pa.

-

Multiple Stages Short Path Wiped Film Molecular Distillation Machine

Multiple Stages Short Path Wiped Film Molecular Distillation Machine applies the principle of molecular distillation, a special technique for physical separation using the difference of the molecular weight. Different from the traditional separation principle based on boiling point. Molecular distillation can solve lots of problems that are difficult to be solved by conventional technology separation. The production process is green and clean, and has a wide application prospect.

-

New style Fruit Food Vegetable Candy Vacuum Freeze Dryer Machine

Our home freeze dryer is a compact vacuum freeze dryer designed for small-scale freeze drying needs in households. It allows you to freeze dry a small quantity of items in the comfort of your home. With its advanced technology and user-friendly interface, our home freeze dryer provides a convenient and efficient solution for preserving candy, food, herbs, and other perishable items.

-

Vacuum Freeze Dryer for Household Use

Household freeze dryer is a kind of small vacuum freeze dryer. Suitable for the use of small amount of lyophilization at home, is a trend of lyophilization machine from special use to civil and household development.

-

Stainless Steel Filter Centrifuge Machines For Herbal Oil Extraction

CFE Series Centrifuge is an extraction and separation device that uses centrifugal force to separate liquid and solid phases. Firstly, the biomass is soaked in solvent, and the active ingredients are fully dissolved in the solvent through low speed and repeated foreward & reverse rotation of the drum.

Through the strong centrifugal force generated by the high speed rotation of the drum, the active ingredients are separated and collected along with the solvent, and the remaining biomass are left in the drum.

-

RFD Series Home Use Fruit Vegetable Liquid Vacuum Freeze Dryer

Household Vacuum Freeze Dryer is a kind of small vacuum freeze dryer, suitable for small amounts of freeze-drying use at home. This is a trend of Freeze-drying Technology from special use to civilian development.

According to whether the Household Vacuum Freeze Dryer has the material pre-freezing function, it can be divided into Traditional Household Freeze Dryer (Without Pre-freezing Function) and In-situ Household Freeze Dryer (With Pre-freezing Function).