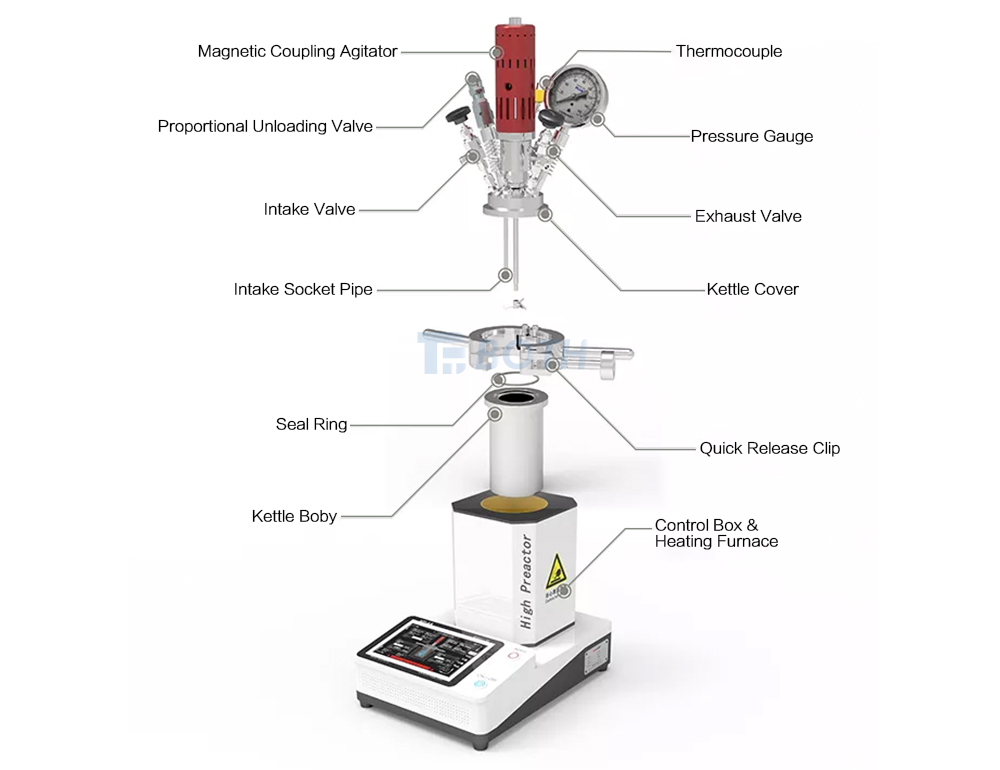

Lab Scale Micro High Temperature High Pressure Temperature Reactor

● Volume: 25 ml, 50 ml, 100 ml, 200 ml, 500 ml for custom-ordering

● Body material: stainless steel 316L/pure titanium/Hastalloy material (optional)

● Working temperature: 250 ℃ / 450 ℃ (optional)

● Working pressure: 10 MPa / 60 MPa (optional)

● Valve and connection materials: SU316L stainless steel

● Reactor liner: PTFE, PPL, quartz glass (optional), liner has advantages of strong anti-corrosion, easy to disassemble and convenient to clean, etc.

● Optical window material: adopted polishing JGS2 quartz glass (pressure-proof window) or sapphire mirror

● Optical window diameter: 30 mm - 60 mm (optional)

● Temperature-control heating device and uniform heat transfer design

● Gas inlet function

● Online temperature and online pressure display

● Strong magnetic stirring function under bottom (users can choose our company’s overhead mechanical stirring method in case of high viscosity or large granular solid materials optionally)

● There has auxiliary cooling or heating function in reactor

● With a high precision adjustable auto-decompression protection

● Two or more online charging function under high temperature and high pressure (optional)

● With the gas phase, liquid phase online detection connection pipe

HT-LCD Display,key Operation

HT-FC Design

(F series,Magnetic stirring)

HT-KJ Design

(K series,Mechanical stirring)

HT-YC Design

(Y series,Magnetic stirring)

ZN-Touch Screen Operation

ZN-FC Design

(F series,Magnetic stirring)

ZN-KJ Design

(K series,Mechanical stirring)

ZN-YC Design

(Y series,Magnetic stirring)

|

Model |

F series |

K series |

Y series |

|

structural style |

Upper and lower flanges, bolt and nut fastening structure |

Semi open loop quick opening structure |

One key quick opening structure |

|

Full volume |

10/25/50/100/250/500/1000/2000ml |

50/100/250/500ml |

50/100/250/500ml |

|

Mechanical mixing is applicable to the volume of 100ml and above |

|||

|

Operating conditions (maximum) |

300℃&10Mpa,Customizable high temperature and high pressure |

300℃&10Mpa |

250℃&10Mpa |

|

texture of material |

Standard 316L, customized Hastelloy / Monel / Inconel / titanium / zirconium and other special materials |

||

|

Valve nozzle |

1 / 4 "inlet valve, 1 / 4" exhaust valve, thermocouple, pressure gauge, safety valve, mixing (mechanical mixing) and spare port respectively |

||

|

Sealing material |

Graphite metal sealing ring |

Modified polytetrafluoroethylene |

Imported perfluoroether |

|

Mixing form |

C-type magnetic stirring, J-type mechanical stirring. Maximum speed: 1000rpm |

||

|

Heating mode |

Integrated pouring electric heating furnace with heating power of 600-1500w. Non standard customized jacket external circulation heating |

||

|

control mode |

HT LCD display, key operation; Zn touch screen display operation with data storage and record export |

||

|

Overall dimension |

Min:305*280*465mm Max:370*360*700mm |

||

|

Power Supply |

AC220V 50Hz |

||

|

Optional function |

Process feed, built-in cooling coil, process sampling, condensation reflux or recovery, etc |

||