High Quality Stainless Steel Short Path Molecular Distillation Unit

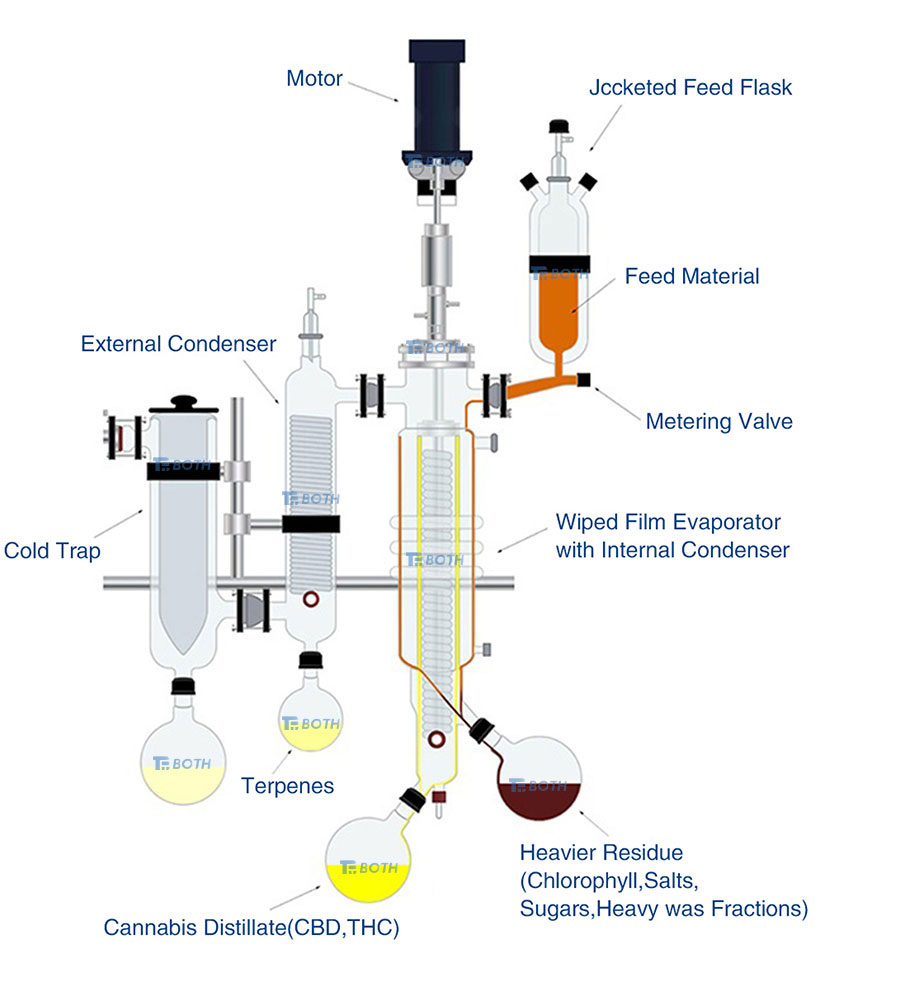

● Continuous feeding & discharge, user don’t have to break vacuum.

● Short residence time.

● High evaporation rates.

● Low processing temperatures.

● Compact design.

● Automatic control.

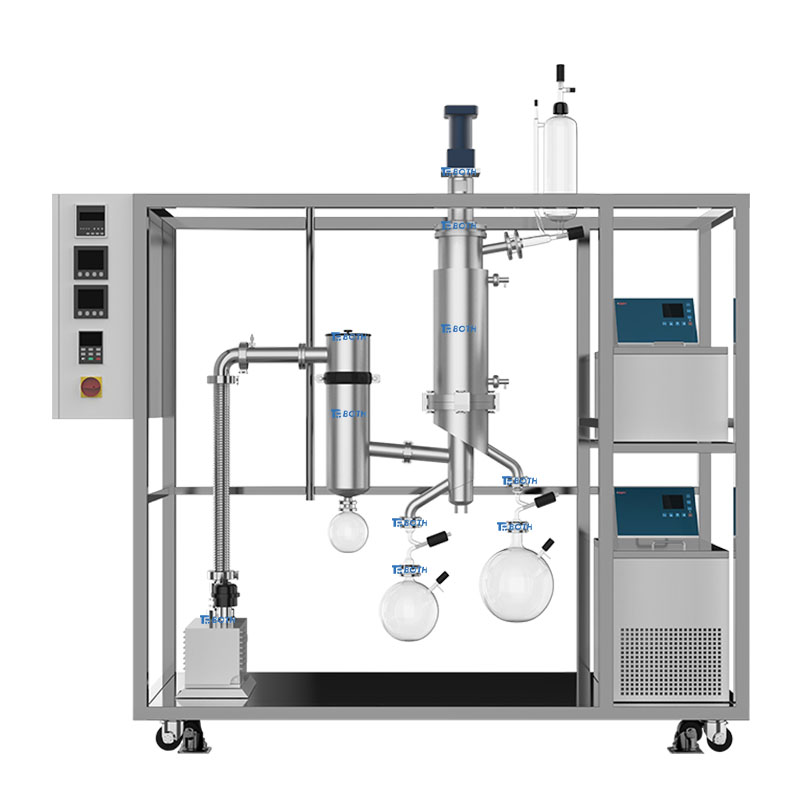

SMD-A Series

Lower Cost Solution, Wide Application, Suitable for Separation & Purification of Most Materials.

● The Lowest Cost to Meet the Requirements of Laboratory R&D Stage.

● High Vacuum (0.01mbar/1Pa), Suitable for Separation and Purification of Most Materials.

● Because Thermal Conductivity of Stainless Steel is Better, The General Processing Capacity of Stainless Steel Equipment with The Same Specifications Is Greater Than Glass Equipment.

● No-Stop Continuous Feeding, Continuous Receiving to Test The Performance of Materials in Different Conditions.

● Compact Design, Firm & Durable, Installation Space Saving. Removable Whole Set, Convenient Operation.

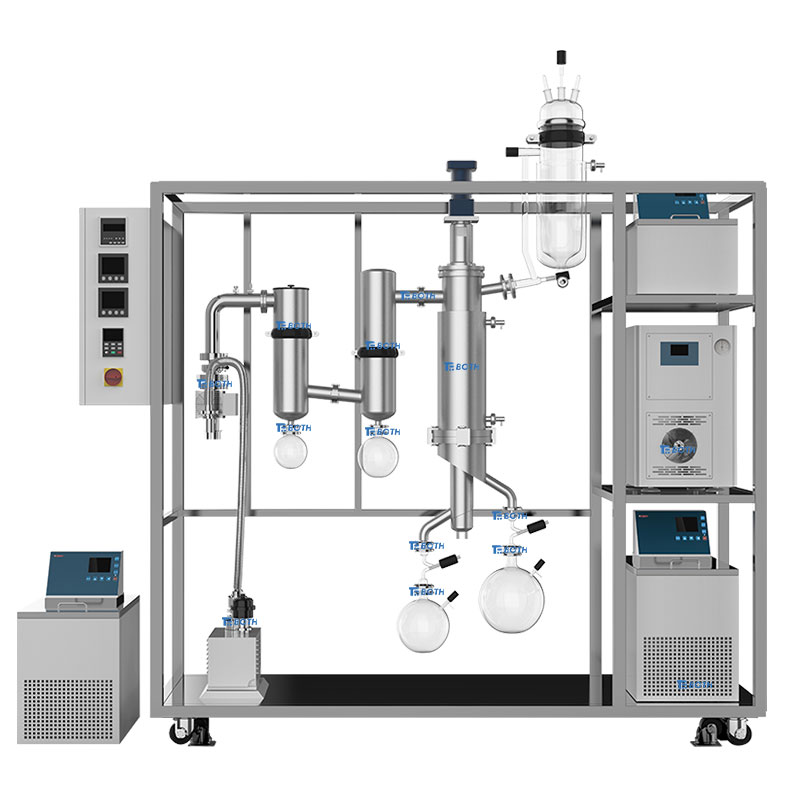

SMD-B Series

High Efficiency Solution, Suitable for Separation & Purification of High Melting Point, High Boiling Point Materials .

● Upgrade the Condensing System, Improve the Vacuum & Distillation Temperature.

● High Vacuum (0.001mbar/0.1Pa) & High Distillation Temperature (300°C), Suitable for Separation and Purification of Materials with High Melting Point and High Boiling Point.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, Not Only with Fractionation Distillation, But also can Effective Protect Vacuum System.

● No-Stop Continuous Feeding, Continuous Receiving to Test The Performance of Materials in Different Conditions.

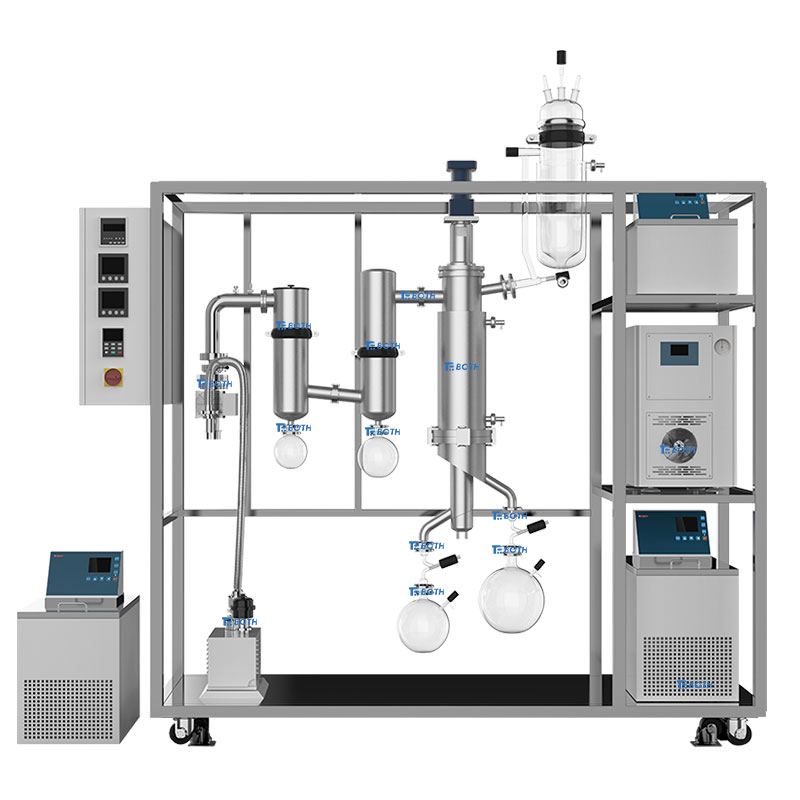

SMD-C1 Series

Fully Jacketed Thermal Insulation & Automatic Feeding/Receiving Solution, Suitable for Heat Sensitive, Good Fluidity of Neutral Materials.

● Upgrade to Full Jacket and Heating Tracing of the Whole Process. Automatic Continuous Feeding & Discharging.

● Feed Pretreatment Adopts Heating Plate Instantaneous Heating, Which Is Suitable for Neutral Materials with Heat Sensitivity & Good Fluidity.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, The Closed Type Coil Cold Trap Instead of Traditional Open Cold Trap to Reduce The Consumption.

● Continuous Feeding and Discharging, Maintain the System Constant Vacuum, Realize Pilot Scaled Continuous Production.

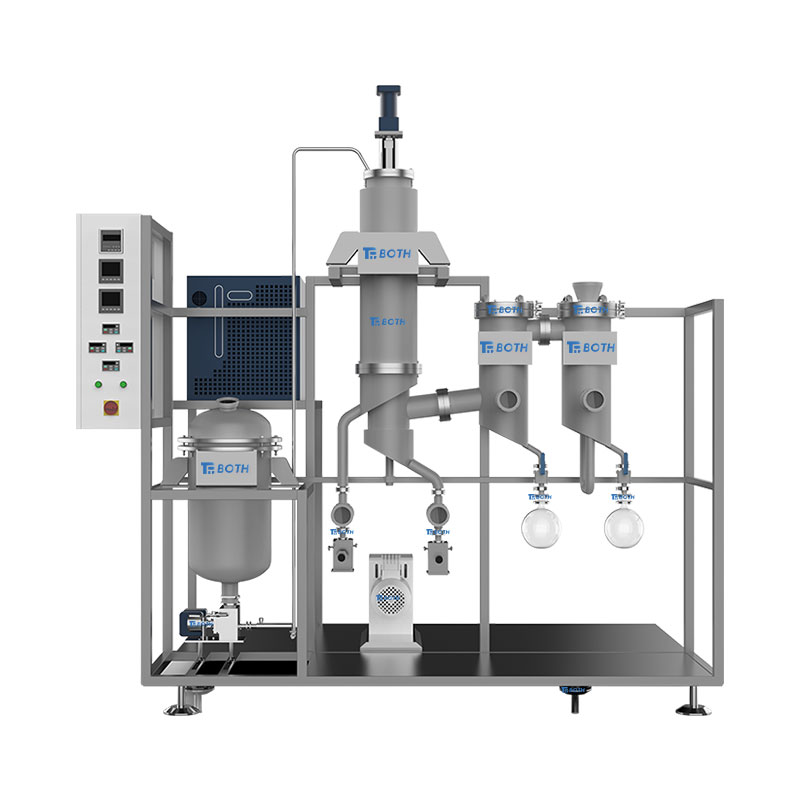

SMD-C2 Series

Fully Jacketed Thermal Insulation & Automatic Feeding/Receiving Solution, Suitable for High viscosity, High Melting Point, High Boiling Point Materials.

● Upgrade to Full Jacket and Heating Tracing of the Whole Process. Automatic Continuous Feeding & Discharging.

● Heating Tracing During the Whole Process, Suitable for Materials with High Viscosity, High Melting Point and High Boiling Point.

● High Power Discharing Gear Pump with Heat Preservation, Avoid Coking & Blocking.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, The Closed Type Coil Cold Trap Instead of Traditional Open Cold Trap to Reduce The Consumption.

● Continuous Feeding and Discharging, Maintain the System Constant Vacuum, Realize Pilot Scaled Continuous Production.

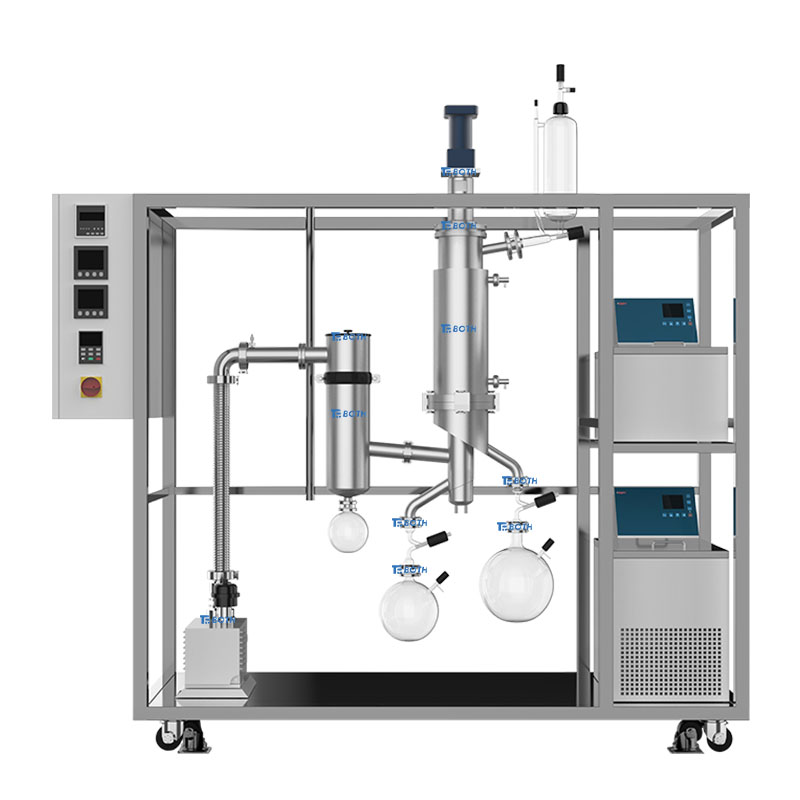

SMD-Plus Series

New Upgrade Solution, Suitable for All Materials.

● Heating Tracing During the Whole Process, Suitable for Materials with High Viscosity, High Melting Point and High Boiling Point.

● New Design Structure, Lower Feeding Height, More Convenient for Operation.

● Enlarge the Feeding Tank Capacity, Saving the Pretreatment Time.

● Equipped with Mini-Adjustable Vacuum Valve, User can Adjust The Vacuum Degree in Real Time.

● Variety of Optional Vacuum Configurations, Such as Diffusion Pump, Turbo Molecular Pump, Roots Pump, Dry Screw Vacuum Pump, Etc., to Adapt to All Kinds of Materials.

| Model | SMD-60 | SMD-80 | SMD-100 | SMD-150 | SMD-200 | SMD-230 |

| Barel Diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Effective Evaporation Area (㎡) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Feeding Rate (kg/h) | 0.1~3 | 0.1~5 | 0.2~7 | 0.5~9 | 0.5~16 | 0.5~26 |

| Feeding Tank Volume (L) | 1.5 | 1.5 | 1.5 | 2 | 5 | 5 |

| Distillate Receiving Flask (L) | 1 | 1 | 2 | 5 | 10 | 10 |

| Residue Receiving Flask (L) | 1 | 1 | 2 | 5 | 10 | 10 |

| Motor Power (W) | 120 | 120 | 120 | 120 | 120 | 200 |

| Rotation Speed (PRM) | 450 | 450 | 450 | 450 | 300 | 300 |

| Designed No-loading Vacuum | 0.001 mbar | |||||

| Operation Temperature | Up to 300℃ | |||||

| Power Supply | 220V/50~60Hz (Other Options Can Be Provided) | |||||