Glass Wiped Film Molecular Distillation Equipment

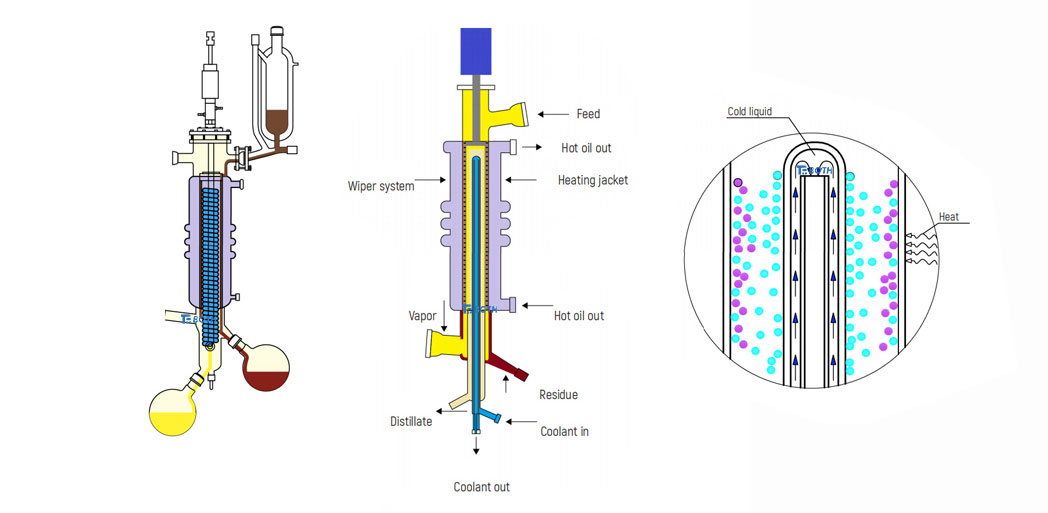

● High evaporation efficiency and reduced retention time, with minimal time delay.

● Short path distilation is ade from high borosiicate glass 3.3 and PTFE, which have excellent corrosion resistance.

● Main body of Short path distilation is made of high boroslicate glass 3.3, allowing the whole process to be observed very clearly.

● High-precision distilation barel allows the iquid to form a complete and unifed thin film on the heated surface. The smooth inneisurface. avoid stick and scaling.

● Higher efficiency distillation, the distance between distilation surface and condenser surface is shorter to 18mm.

● German technology brand frequency conversion deceleration motor, with self-cooling fan, long time continuous working.

● Magnetic force transmission make film forming syster separate from motor, the top sealing of distilation barrel have no dwangthrough. The whole System performs a completed sealing. Min Vacuum degree can reach 1Pa.

● Highest temperature of the system can reach 260'C, accurate temperature control can be realized.

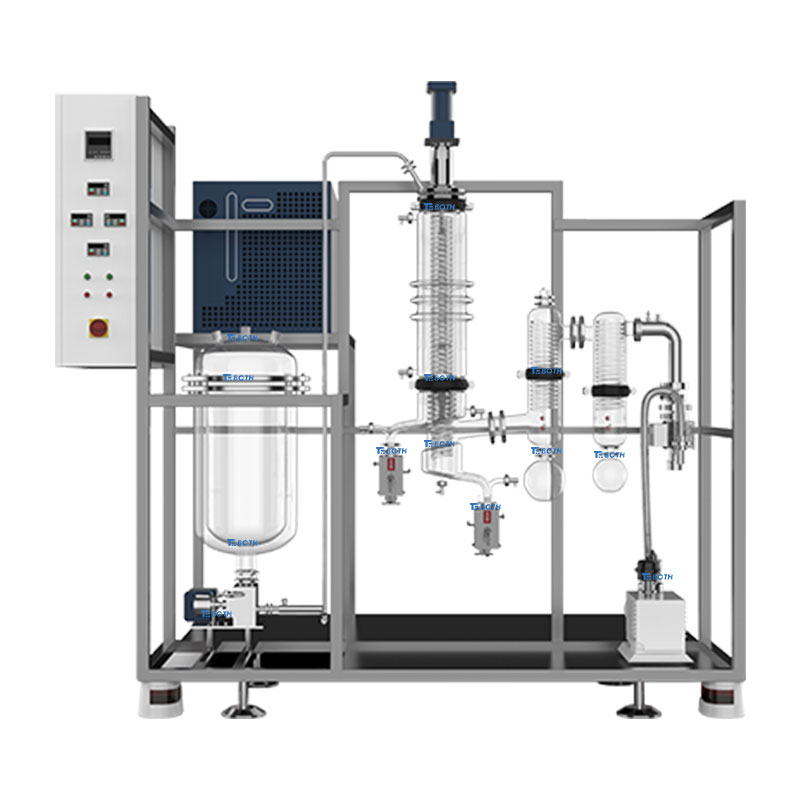

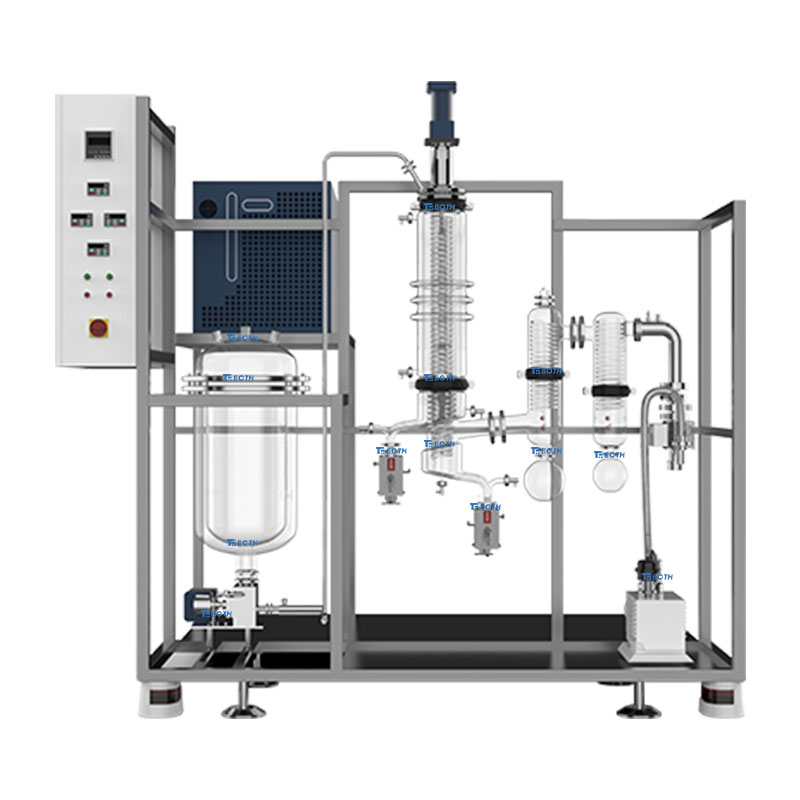

GMD-A Series

Lower Cost Solution, Wide Application, Suitable for Separation & Purification of Most Materials.

● The Lowest Cost to Meet the Requirements of Laboratory R&D Stage.

● High Vacuum (0.01mbar/1Pa), Suitable for Separation and Purification of Most Materials.

● Visible the Whole Working Process,Experiments Condition Can be Adjusted In Time to Save Users' Precious Time.

● No-Stop Continuous Feeding, Continuous Receiving to Test The Performance of Materials in Different Conditions.

● Compact Design, Installation Space Saving. Removable Whole Set, Convenient Operation.

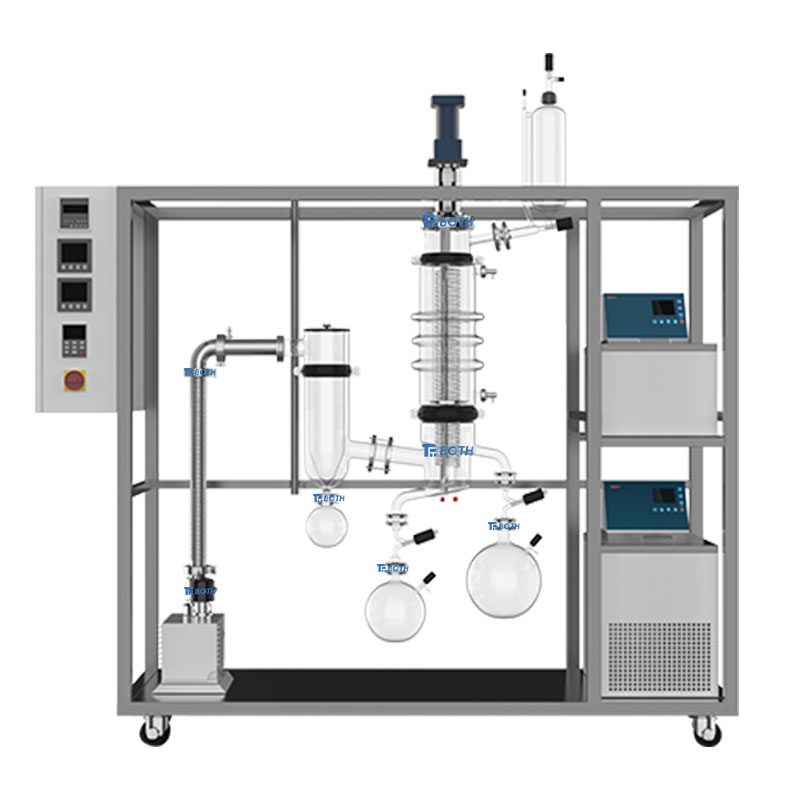

GMD-B Series

High Efficiency Solution, Suitable for Separation & Purification of High Melting Point, High Boiling Point Materials.

● Upgrade the Condensing System, Improve the Vacuum & Distillation Temperature.

● High Vacuum (0.001mbar/0.1Pa) & High Distillation Temperature (300°C), Suitable for Separation and Purification of Materials with High Melting Point and High Boiling Point.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, Not Only with Fractionation Distillation, But also can Effective Protect Vacuum System.

● No-Stop Continuous Feeding, Continuous Receiving to Test The Performance of Materials in Different Conditions.

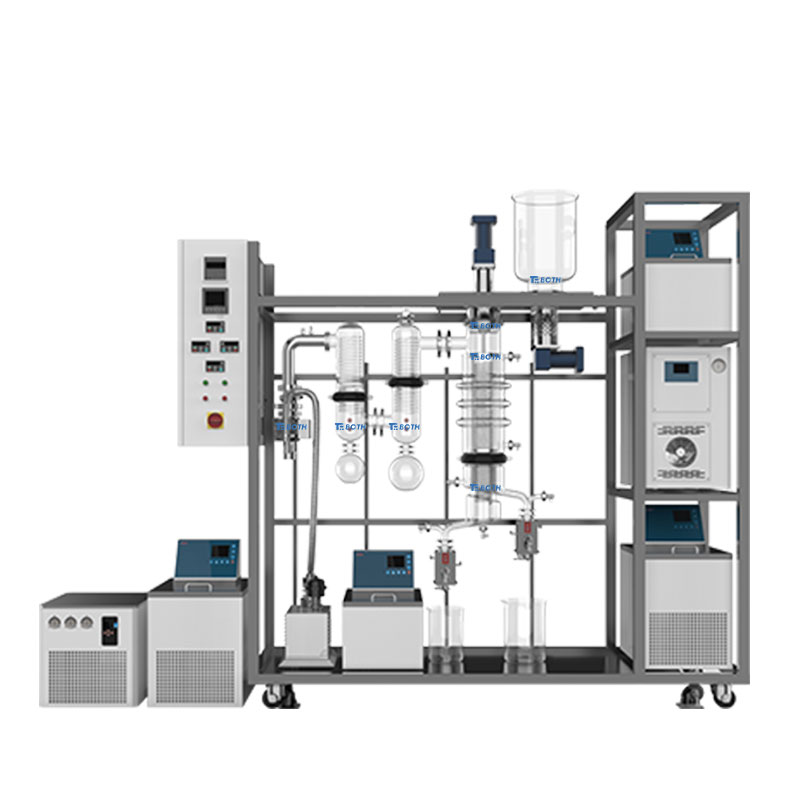

GMD-C1 Series

Fully Jacketed Thermal Insulation & Automatic Feeding/Receiving Solution, Suitable for Heat Sensitive, Good Fluidity of Neutral Materials.

● Upgrade to Full Jacket and Heating Tracing of the Whole Process. Automatic Continuous Feeding & Discharging.

● Feed Pretreatment Adopts Heating Plate Instantaneous Heating, Which Is Suitable for Neutral Materials with Heat Sensitivity & Good Fluidity.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, The Closed Type Coil Cold Trap Instead of Traditional Open Cold Trap to Reduce The Consumption.

● Continuous Feeding and Discharging, Maintain the System Constant Vacuum, Realize Pilot Scaled Continuous Production.

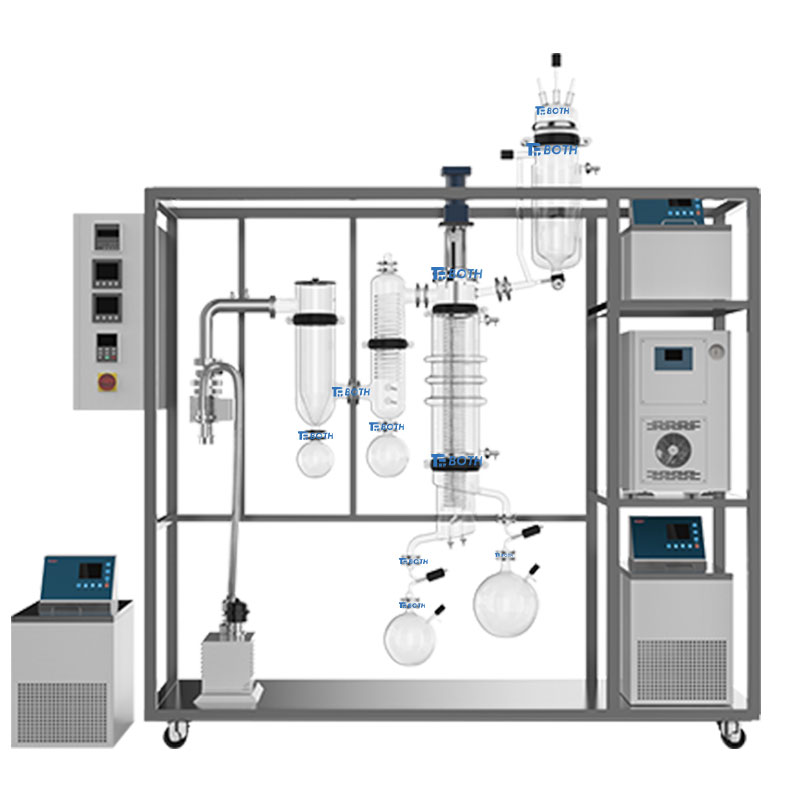

GMD-C2 Series

Fully Jacketed Thermal Insulation & Automatic Feeding/Receiving Solution, Suitable for High viscosity, High Melting Point, High Boiling Point Materials.

● Upgrade to Full Jacket and Heating Tracing of the Whole Process. Automatic Continuous Feeding & Discharging.

● Heating Tracing During the Whole Process, Suitable for Materials with High Viscosity, High Melting Point and High Boiling Point.

● High Power Disc-haring Gear Pump with Heat Preservation, Avoid Coking & Blocking.

● Completed Closed High Temperature Circulator, Smokeless and No Smell, No Pollution.

● Dual Condensation System, The Closed Type Coil Cold Trap Instead of Traditional Open Cold Trap to Reduce The Consumption.

● Continuous Feeding and Discharging, Maintain the System Constant Vacuum, Realize Pilot Scaled Continuous Production.

GMD-Plus Series

New Upgrade Solution, Suitable for All Materials.

● Heating Tracing During the Whole Process, Suitable for Materials with High Viscosity, High Melting Point and High Boiling Point

● New Design Structure, Lower Feeding Height, More Convenient for Operation

● Enlarge the Feeding Tank Capacity, Saving the Pretreatment Time

● Equipped with Mini-Adjustable Vacuum Valve, User can Adjust The Vacuum Degree in Real Time

● Variety of Optional Vacuum Configurations, Such as Diffusion Pump, Turbo Molecular Pump, Roots Pump, Dry Screw Vacuum Pump, Etc., to Adapt to All Kinds of Materials

| Model | GMD-60 | GMD-80 | GMD-100 | GMD-150 | GMD-200 | GMD-230 |

| Barel Diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Effective Evaporation Area (m²) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Feeding Rate (kg/h) | 0.1~2 | 0.1~4 | 0.2~6 | 0.5~8 | 0.5~15 | 0.5~25 |

| Feeding Flask Volume (L) | 1.5 | 1.5 | 1.5 | 2 | 5 | 5 |

| Distillate Receiving Flask (L) | 1 | 1 | 2 | 5 | 10 | 10 |

| Residue Receiving Flask (L) | 1 | 1 | 2 | 5 | 10 | 10 |

| Motor Power (W) | 120 | 120 | 120 | 120 | 120 | 200 |

| Rotation Speed (PRM) | 450 | 450 | 450 | 450 | 300 | 300 |

| Designed No-loading Vacuum | 0.001 mbar | |||||

| Operation Temperature | Up to 300°C | |||||

| Power Supply | 220V/50~60Hz (Other Options Can Be Provided) | |||||