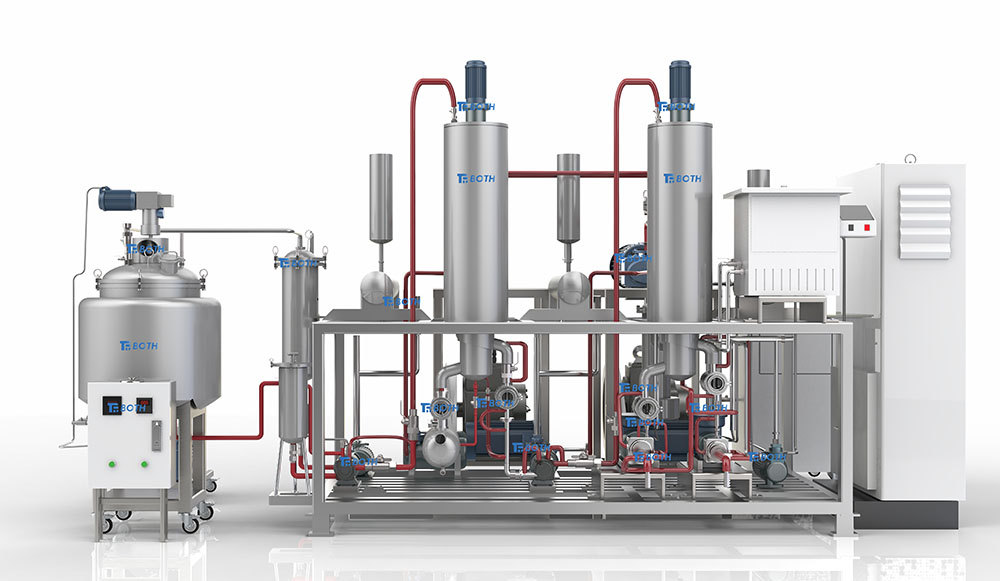

2 Stages Short Path Wiped Film Distillation Machine

● Continuous feeding & discharge, industrial grade high precise magnetic driving gear pump.

● Pretreatments are integrated, such as decarboxylation or degassing.

● Heating preservation, full jacketed pipelines, transfer pump, feeding pump and discharge pump.

● High Vacuum, industrial grade vacuum pump unit (Rotary Vane Oil Pump + Roots Pump + Diffusion Pump)

● Process visibility,60 mm big diameter sight windows make every process clearly.

● Long time service life, no coking or jam in long time running.

| Model | MMD-03-2 | MMD-05-2 | MMD-1-2 | MMD-2-2 | |

| *Throughput | Suggest Feeding Rates (KG/HOUR) | 3~6 | 8~12 | 25~40 | 80~100 |

| Herbal Throughput (KG/HOUR) | 2~4 | 6~8.5 | 20~30 | 60~70 | |

| Whole System Vacuum Degree | 0.01mbar/1Pa | ||||

| Evaporator *2 Units | Evaporation Area (M²) | 0.3 m² | 0.5 m² | 1.0 m² | 2.0 m² |

| Internal Condensation Area (M²) | 0.6 m² | 1.0 m² | 2.0 m² | 4.0 m² | |

| Evaporator Outside Diameter (mm/") | 230mm/9.1" | 350mm/13.8" | 510mm/20.1'' | 690mm/27.2" | |

| Evaporator Inside Diameter (mm/") | 150mm/5.9'' | 200mm/7.9'' | 305mm/12'' | 510mm/20.1'' | |

| Evaporator Height (mm/") | 450mm/17.7'' | 800mm/31.5‘’ | 1050mm/41.3'' | 1200mm/47.2'' | |

| Wiper Style | Scraper | ||||

| Wiper Material | SS316L(Support) / PTFE+ Graphite composited (Wiper blade) | ||||

| Sealing Type | Magnetic Sealing | ||||

| Rotor Motor Power (W) | 120 | 200 | 400 | 750 | |

| Speed Regulation Mode | Variable Frequency Drive / VFD | ||||

| Max. Rotate Speed (RPM) | 140 RPM | ||||

| Max. Temperature | 280°C | ||||

| Dehydration & Degassing Feeding Vessel | Volume(L) | 50 L | 50 L | 100 L | 200 L |

| Heating Method | Electrical Heating | ||||

| Heating Power (KW) | 2 KW | 4 KW | 5 KW | 6 KW | |

| Stirring Power (W) | 200W | 370W | 550W | 550W | |

| Max. Stirring Speeding (RPM) | 50 | 40 | 30 | 25 | |

| Feeding Filter | Filtration Bore Diameter (UM) | 50~100 | 50~100 | 50~100 | 50~100 |

| Capacity (L/HOUR) | 50 | 100 | 150 | 200 | |

| Feeding Pump | Flowing Rate (L/HOUR) | 10 | 20 | 50 | 100 |

| Lift (Mpa) | 0.2 Mpa | 0.2 Mpa | 0.2 Mpa | 0.2 Mpa | |

| Power (W) | 120W | 200 W | 200W | 400W | |

| Transfer Pump Between Stages/Magnetic Driving Pump | Flowing Rate (L/HOUR) | 10 | 20 | 50 | 100 |

| Lift (Mpa) | 0.3 Mpa | 0.3 Mpa | 0.3 Mpa | 0.3 Mpa | |

| Power (W) | 120W | 200 W | 200W | 370W | |

| Discharging Pump /Magnetic Driving High Precise Gear Pump*3 Sets | Flowing Rate (L/HOUR) | 10 | 20 | 50 | 100 |

| Lift (Mpa) | 0.3 Mpa | 0.3 Mpa | 0.3 Mpa | 0.3 Mpa | |

| Power (W) | 120W | 200 W | 200W | 370W | |

| Heating Preservation | Method | Jacketed Insulation, Secondary Heater Provide Heating Separately | |||

| Heat Tracing Parts | All the transfer pipelines, transfer pump, feeding pump and discharge pumps | ||||

| Support Frame | Material | SUS 304 | |||

| General Information | Dimension (L*W*H / m) | 2.0*2.0*2.4 | 2.5*2.4 *2.4 | 3.3*5.0*4.5 | 10*5.8*5.4 |

| Weight (KG) | 600 | 1000 | 1800 | 2300 | |

| Power (KW) | 18 | 24 | 80 | 110 | |

| Optional: | Replace Traditional Dry Ice or Liquid Nitrogen | ||||

| Optional A./ Super Cryogenic Machine | Temperature Range (°C) | -80°C~RT | |||

| Refrigeration Power (W) | 1471 W | 2206 W | 2942 W | 4413 W | |

| Lift (M) | 15 M | 15 M | 18 M | 20 M | |

| Circulation Rate (L/HOUR) | 8 | 10 | 12 | 15 | |

| Optional B./ Super Cryogenic Machine B. | Temperature Range (°C) | -120°C~RT | |||

| Refrigeration Power (W) | 2800 W | 4400 W | 5800 W | 8400 W | |

| Lift (Meter) | 15 M | 15 M | 18 M | 20 M | |

| Circulation Rate (L/HOUR) | 8 | 10 | 12 | 15 | |

1) Why I see a different process capacity from other suppliers? Especially both of the equipment have same figure of evaporation area?

Generally speaking, normal process capacity is depend on the evaporation area. Once the evaporation area is fixed, then the normal process capacity is also fixed.

Since different feeding material with different nature, there will be a specific process capacity.

Specific process capacity is usually smaller than normal. For example, specific process capacity of hemp oil should be half of the normal capacity due to the high viscosity.

Besides that, the heating temp. Setting or vacuum degree would affect the process capacity, the affect will be every slight, though.

2) What's the specific process capacity for this machine?

We have 4 models for different process capacity.

MMD-03-2, 3~6 L/HOUR (Specific Process Capacity, Suggested)

MMD-05-2, 8~12 L/HOUR (Specific Process Capacity, Suggested)

MMD-10-2, 25~40 L/HOUR (Specific Process Capacity, Suggested)

MMD-20-2, 80~100 L/HOUR (Specific Process Capacity, Suggested)

3) Is it a turnkey machine?

Yes! It is a turnkey machine come with all the supporting facilities such as heater, chiller and vacuum

4) What are the advantages for this 2 stages molecular distillation machine?

This 2 stages molecular distillation machine assembles with dehydration and degassing reactor, which will make a pre-treatment before distillation.

All the pipe lines, the transfer magnetic pump, feeding pump and discharging gear pumps are heat tracing. These designs will avoid any coking and block in long time running.

5) 2 stages molecular distillation machine VS single stage one?

Compare with single stage molecular distillation machine.

Only one pass operation, user can receive higher yield and higher purity Herbal oil.

While, the price is much less than 2 sets of single stage molecular distillation machine.

6) Do you have after-sales service?

Yes! We provide 24-hour online support, video technical support and free spare parts for free.

Overseas field Installation, commissioning and training is also available.